BACK

Written by: Qballcious

Before you start. Put the transmission in 1st gear if it's Manual. Make sure it's in "park" if it's an automatic. I had my Terc on 4 jackstands so I did none of that.

Jack up the back of the car using the factory lift points on the rocker panels and then place jack-stands under the rear axle. Now remove the wheel.

Let's get down to business.

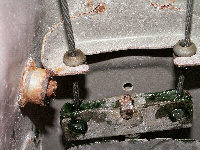

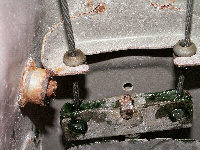

This is the little nasty rusty drum brake setup Toyota equiped our Tercels with. Although completly adequate for the weight of the vehicle, it just looks plain fugly when you've got some sweet alloys on your ride.

Start by removing the dust cover using a flat-head screwdriver/chisel and a hammer. Tap the cap alternating sides to pop it off.

Now you'll see the cotterpin and nut retainer. Remove the pin using a set of needle-nose pliers to straighten the pin legs and then pull it out. The nut retainer should come right off after the pin has been removed.

Now remove the nut with a 22mm socket. Both sides of the car use regular thread. No reverse threads here. So "righty-tighty, lefty-loosy" applies here too.

Remove the washer. The bearing should now come out easily.

After the bearing has been removed the drum should come off. There may be some hesitation. If you need better leverage, try putting the wheel back on with a couple of lugnuts and use it for leverage. There is also an adjuster inside the drum brake assembly that can be accessed through a hole in the backing plate which is plugged with a rubber grommet. Release the shoes like that if you just can't get the drum off otherwise. Older drums usually have lips worn into the drum which makes them harder to remove.

This is what you should be looking at after removing the drum.

Remove the giant retractor spring by prying it off with a screwdriver or do like I did and use your hands. It's really not all that stiff. It's function is to retract the brake shoes when you let off the brake pedal.

Next you need to remove the retaining pins. These hold the brake shoes in place. There's one in each shoe. Reach around back with one hand and hold the pin in place. Then with the other hand, push the front washer in and twist to release the washer. Now remove the pin, spring and both washers.

You should be able to remove the shoes one at a time. Remember not to lose the bottom spring that connects the two shoes.

Now remove the e-brake cable. Just pull the spring back with your hand and slip the cable out of the bracket.

Release the e-brake cable from the backing plate by removing the two little bolts with a 10mm socket.

Now it's time to get under the car and unbolt the solid brake line from the axle. A standard open-end wrench will most likely strip the nut so use a linewrench. This is a special wrench that has more contact surface than an open ended wrench which will protect the nut and allow you to loosen even the most stubborn nut. It's like a box-ended wrench with a slot in it to slip over the pipe.

Now unbolt the backing plate from the axle by removing the 4 bolts with a 14mm socket.

It's now time to prep the Starlet GT disc rotors. I know it's really rusty but I love it.

Remove the old inner bearing seal with this wicked seal puller. That seal puller looks like a weapon you say? Well I'd have to agree. After pulling the old seal. The bearing comes right out.

Let's hit the parts washer for some cleanup. You can tell I love this part....mmm....solvent. Clean the bearing out well and then blow it out with compressed air. You want to get ALL the old grease out. Do the same for the rotor.

So fresh and so clean-lean-lean...sorry....anyways - back at the ranch...

Repack the bearings with wheel bearing grease. I do it manually but you can use a bearing packer. You can use either the Tercel or Starlet bearings. But I prefer to use the Starlet bearings since the race is installed in the rotor already. Make sure to put some grease in the cavity of the rotor too to make sure the bearings will always have grease.

Now it's time to re-install a new Genuine Toyota Japanese built inner bearing seal. Again the USDM/CDM 91-99 Tercel seals fit the Starlet GT rotors.

I didn't get a pic of the seal driver I used so here's what it looks like on top of the old drums. Use it to pound the new seal in nice and straight. Apply some wheel grease to inside of the seal to protect it later during sintallation.

Now that the rotors are preped it's time to go back to the axle. Clean off the flat mating surface with a wire brush and sand paper. Then cover it with anti-cease just in case you ever need to remove it in the future. Bolt on the new backing plate with the longer bolts from the starlet GT setup. The Tercel bolts are too short.

Coat the spindel with some more axle/wheel grease to protect the seal during installation. Slide the rotor onto the spindel and re-install the newly re-packed outter bearing, washer, nut, nut retainer, cotter pin, and dust cap. All those parts can be used from either your Tercel or the Starlet. They are all interchangable.

Bolt the caliper bracket to the backing plate. 12mm wrench. Now's also a good time to clean the rotors off with some aerosol brake cleaner to get all the grease and solvent off before installing new pads.

Open up one of your boxes of brand new Genuine Toyota pads. Install the pad shims. Again..rusty I know. Use some anti-squeek and apply it to the contact patch of the shims.

Time to prep the caliper. I had already rebuilt these but I had a couple of pieces left. Copper washers for the flexible brake hose.

Make sure to retract and rotate the piston into this position before bolting the caliper to the bracket. The little bumps/tabs on the brake pads have to fit into that slot in the piston to keep it from rotating. So make sure it's installed properly.

Now snap the other end of the hose in place on the bracket with the C-pin.

Attach the hard line from the Starlet setup. The Tercel line doesn't fit. You may be able to bend it to fit but if you have the Starlet lines, use them. IF you don't want to wreck your Tercel setup, then go out and buy some hard lines with connectors and bend it to suit your needs. They cost less than $10 each.

Sh!t that's sexy.

Ok when you're done admiring your own work it's time to get messy again. Time to hook up the Starlet GT e-brake cables. I won't sugar coat it. This part suxorz.

You have to remove the aluminum exhaust heat shield to get at the e-brake cables.

You're gonna have to make some room to work in there so unhook the rear muffler hanger and slide the whole exhaust off to either side.

Then using a large drilbit to drill out the 3 aluminum rivets that hold the shield in place. Don't worry. You can re-install it later.

Now get in the car and take your 10mm socket, extenssion and ratchet with you. Loosen the adjustor nut as far as you can without backing it off the bolt all together.

Get back under the car and remove the cables with a 10mm socket.

Now you'll run into a problem. At least I did on my 98 Tercel.

Starlet cable on the left - Tercel cable on the right. I had to fab up some sleeves out of a piece of 10mm conduit to solve the problem. MINT!!!!

Unfortunatly the Starlet is a little shorter than a Tercel so it's cables too are a little shorter than the Tercel's. So you can only use one mounting point on each side.

Route the cable through the stock location on the axle. You will have to remove the grommet and then pass the cable through the hole. Reinstall the grommet over the cable and squeeze it back into the hole.

I didn't get any pins to attach the cables to the rear calipers so I had to make some. I used some TOYOTA bolts that I had lying around. I cut them to length and drilled them for a cotter pin.

Now that you're done with the cables you can re-install the heat shields using some standard aluminum pop-rivets.

Go back into the cab and tighten that e-brake tentioner nut.

That's it. You're done. Now just bleed the brakes and top off the brake fluid. Put the wheels back on and you're ready for a test run. BTW this setup will fit with 13" stock wheels.

Good luck guys.

BACK